Page 23 - Raport_engleza_2019

P. 23

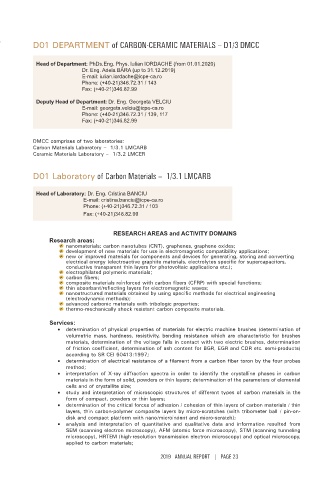

D01 DEPARTMENT of CARBON-CERAMIC MATERIALS – D1/3 DMCC

Head of Department: PhDs.Eng. Phys. Iulian IORDACHE (from 01.01.2020)

Dr. Eng. Adela BĂRA (up to 31.12.2019)

E-mail: iulian.iordache@icpe-ca.ro

Phone: (+40-21)346.72.31 / 143

Fax: (+40-21)346.82.99

Deputy Head of Department: Dr. Eng. Georgeta VELCIU

E-mail: georgeta.velciu@icpe-ca.ro

Phone: (+40-21)346.72.31 / 139, 117

Fax: (+40-21)346.82.99

DMCC comprises of two laboratories:

Carbon Materials Laboratory – 1/3.1 LMCARB

Ceramic Materials Laboratory – 1/3.2 LMCER

D01 Laboratory of Carbon Materials – 1/3.1 LMCARB

Head of Laboratory: Dr. Eng. Cristina BANCIU

E-mail: cristina.banciu@icpe-ca.ro

Phone: (+40-21)346.72.31 / 103

Fax: (+40-21)346.82.99

RESEARCH AREAS and ACTIVITY DOMAINS

Research areas:

nanomaterials: carbon nanotubes (CNT), graphenes, graphene oxides;

development of new materials for use in electromagnetic compatibility applications;

new or improved materials for components and devices for generating, storing and converting

electrical energy (electroactive graphite materials, electrolytes specific for supercapacitors,

conductive transparent thin layers for photovoltaic applications etc.);

electrophilated polymeric materials;

carbon fibers;

composite materials reinforced with carbon fibers (CFRP) with special functions;

thin absorbant/reflecting layers for electromagnetic waves;

nanostructured materials obtained by using specific methods for electrical engineering

(electrodynamic methods);

advanced carbonic materials with tribologic properties;

thermo‑mechanically shock resistant carbon composite materials.

Services:

• determination of physical properties of materials for electric machine brushes (determination of

volumetric mass, hardness, resistivity, bending resistance which are characteristic for brushes

materials, determination of the voltage falls in contact with two electric brushes, determination

of friction coefficient, determination of ash content for BGR, EGR and CDR etc. semi‑products)

according to SR CEI 60413:1997;

• determination of electrical resistance of a filament from a carbon fiber toron by the four probes

method;

• interpretation of X‑ray diffraction spectra in order to identify the crystalline phases in carbon

materials in the form of solid, powders or thin layers; determination of the parameters of elemental

cells and of crystallite size;

• study and interpretation of microscopic structures of different types of carbon materials in the

form of compact, powders or thin layers;

• determination of the critical forces of adhesion / cohesion of thin layers of carbon materials / thin

layers, thin carbon‑polymer composite layers by micro‑scratches (with tribometer ball / pin‑on‑

disk and compact platform with nano/microindent and micro‑scratch);

• analysis and interpretation of quantitative and qualitative data and information resulted from

SEM (scanning electron microscopy), AFM (atomic force microscopy), STM (scanning tunneling

microscopy), HRTEM (high‑resolution transmission electron microscopy) and optical microscopy,

applied to carbon materials;

2019 ANNUAL REPORT | PAGE 23