Page 25 - Raport_engleza_2019

P. 25

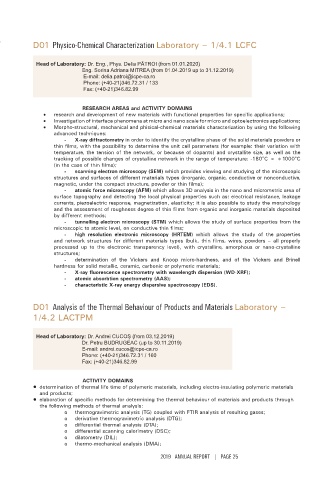

D01 Physico-Chemical Characterization Laboratory – 1/4.1 LCFC

Head of Laboratory: Dr. Eng., Phys. Delia PĂTROI (from 01.01.2020)

Eng. Sorina Adriana MITREA (from 01.04.2019 up to 31.12.2019)

E-mail: delia.patroi@icpe-ca.ro

Phone: (+40-21)346.72.31 / 133

Fax: (+40-21)346.82.99

RESEARCH AREAS and ACTIVITY DOMAINS

• research and development of new materials with functional properties for specific applications;

• Investigation of interface phenomena at micro and nano scale for micro and optoelectronics applications;

• Morpho‑structural, mechanical and phisical‑chemical materials characterization by using the following

advanced techniques:

- X-ray diffractometry in order to identify the crystalline phase of the solid materials powders or

thin films, with the possibility to determine the unit cell parameters (for example: their variation with

temperature, the tension of the network, or because of dopants) and crystallite size, as well as the

tracking of possible changes of crystalline network in the range of temperature: ‑180°C ÷ +1000°C

(in the case of thin films);

- scanning electron microscopy (SEM) which provides viewing and studying of the microscopic

structures and surfaces of different materials types (inorganic, organic, conductive or nonconductive,

magnetic, under the compact structure, powder or thin films);

- atomic force microscopy (AFM) which allows 3D analysis in the nano and micrometric area of

surface topography and detecting the local physical properties such as: electrical resistance, leakage

currents, piezoelectric response, magnetization, elasticity; it is also possible to study the morphology

and the assessment of roughness degree of thin films from organic and inorganic materials deposited

by different methods;

- tunnelling electron microscopy (STM) which allows the study of surface properties from the

microscopic to atomic level, on conductive thin films;

- high resolution electronic microscopy (HRTEM) which allows the study of the properties

and network structures for different materials types (bulk, thin films, wires, powders – all properly

processed up to the electronic transparency level), with crystalline, amorphous or nano‑crystalline

structures;

- determination of the Vickers and Knoop micro‑hardness, and of the Vickers and Brinell

hardness for solid metallic, ceramic, carbonic or polymeric materials;

- X-ray fluorescence spectrometry with wavelength dispersion (WD-XRF);

- atomic absorbtion spectrometry (AAS);

- characteristic X-ray energy dispersive spectroscopy (EDS).

D01 Analysis of the Thermal Behaviour of Products and Materials Laboratory –

1/4.2 LACTPM

Head of Laboratory: Dr. Andrei CUCOȘ (from 03.12.2019)

Dr. Petru BUDRUGEAC (up to 30.11.2019)

E-mail: andrei.cucos@icpe-ca.ro

Phone: (+40-21)346.72.31 / 160

Fax: (+40-21)346.82.99

ACTIVITY DOMAINS

• determination of thermal life time of polymeric materials, including electro‑insulating polymeric materials

and products;

• elaboration of specific methods for determining the thermal behaviour of materials and products through

the following methods of thermal analysis:

o thermogravimetric analysis (TG) coupled with FTIR analysis of resulting gases;

o derivative thermogravimetric analysis (DTG);

o differential thermal analysis (DTA);

o differential scanning calorimetry (DSC);

o dilatometry (DIL);

o thermo‑mechanical analysis (DMA);

2019 ANNUAL REPORT | PAGE 25