Page 72 - Raport_engleza_2019

P. 72

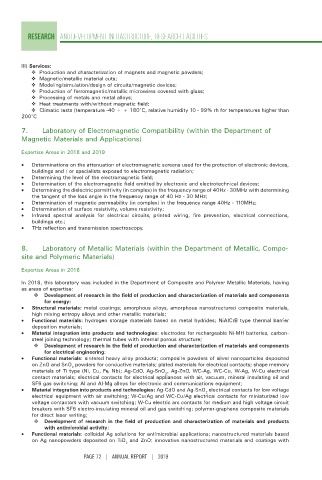

RESEARCH AND DEVELOPMENT INFRASTRUCTURE, RESEARCH FACILITIES

III) Services:

Production and characterization of magnets and magnetic powders;

Magnetic/metallic material cuts;

Modeling/simulation/design of circuits/magnetic devices;

Production of ferromagnetic/metallic microwires covered with glass;

Processing of metals and metal alloys;

Heat treatments with/without magnetic field;

Climatic tests (temperature ‑40 ÷ + 180 C, relative humidity 10 ‑ 99% rh for temperatures higher than

°

200 C

°

7. Laboratory of Electromagnetic Compatibility (within the Department of

Magnetic Materials and Applications)

Expertise Areas in 2018 and 2019

• Determinations on the attenuation of electromagnetic screens used for the protection of electronic devices,

buildings and / or specialists exposed to electromagnetic radiation;

• Determining the level of the electromagnetic field;

• Determination of the electromagnetic field emitted by electronic and electrotechnical devices;

• Determining the dielectric permittivity (in complex) in the frequency range of 40Hz ‑ 30MHz with determining

the tangent of the loss angle in the frequency range of 40 Hz ‑ 30 MHz;

• Determination of magnetic permeability (in complex) in the frequency range 40Hz ‑ 110MHz;

• Determination of surface resistivity, volume resistivity;

• Infrared spectral analysis for electrical circuits, printed wiring, fire prevention, electrical connections,

buildings etc.;

• THz reflection and transmission spectroscopy.

8. Laboratory of Metallic Materials (within the Department of Metallic, Compo‑

site and Polymeric Materials)

Expertise Areas in 2018

In 2018, this laboratory was included in the Department of Composite and Polymer Metallic Materials, having

as areas of expertise:

Development of research in the field of production and characterization of materials and components

for energy:

• Structural materials: metal coatings; amorphous alloys, amorphous nanostructured composite materials,

high mixing entropy alloys and other metallic materials;

• Functional materials: hydrogen storage materials based on metal hydrides; NiAlCrB type thermal barrier

deposition materials;

• Material integration into products and technologies: electrodes for rechargeable Ni‑MH batteries, carbon‑

steel joining technology; thermal tubes with internal porous structure;

Development of research in the field of production and characterization of materials and components

for electrical engineering:

• Functional materials: sintered heavy alloy products; composite powders of silver nanoparticles deposited

on ZnO and SnO powders for conductive materials; plated materials for electrical contacts; shape memory

2

materials of Ti type (Ni, Cu, Fe, Nb); Ag‑CdO, Ag‑SnO , Ag‑ZnO, WC‑Ag, WC‑Cu, W‑Ag, W‑Cu electrical

2

contact materials; electrical contacts for electrical appliances with air, vacuum, mineral insulating oil and

SF6 gas switching; Al and Al‑Mg alloys for electronic and communications equipment;

• Material integration into products and technologies: Ag‑CdO and Ag‑SnO electrical contacts for low voltage

2

electrical equipment with air switching; W‑Cu/Ag and WC‑Cu/Ag electrical contacts for miniaturized low

voltage contactors with vacuum switching; W‑Cu electric arc contacts for medium and high voltage circuit

breakers with SF6 electro‑insulating mineral oil and gas switching; polymer‑graphene composite materials

for direct laser writing;

Development of research in the field of production and characterization of materials and products

with antimicrobial activity:

• Functional materials: colloidal Ag solutions for antimicrobial applications; nanostructured materials based

on Ag nanopowders deposited on TiO and ZnO; innovative nanostructured materials and coatings with

2

PAGE 72 | ANNUAL REPORT | 2019